Innovation in flight and beyond

On March 17 we saw the third Longitude aircraft in the flight test program take to the skies for the first time, paving the way for a new round of testing and development.

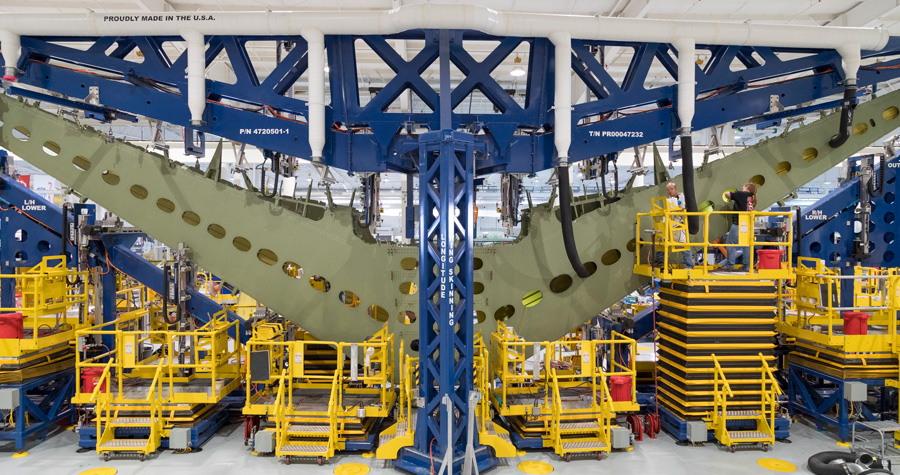

And with assembly line flow officially underway, the first four production Longitude jets are now in progress. From our Plant IV facility in East Wichita, Kan. the manufacturing team is using advanced tooling and state-of-the-art technology unique to Textron Aviation to bring the aircraft to life.

To join the large fuselage sections of the Longitude, manufacturing engineers designed and built a series of vertical assembly tools that are giving assembly technicians the additional space required to build the largest Citation in production. Vertical tooling structures were also developed in-house to help technicians easily build up the 73-foot wing of the Longitude.

It’s an innovative approach to aircraft assembly unseen in the industry, said Ron Draper, Textron Aviation senior vice president, integrated supply chain.

"Not only is it more efficient to build large aircraft like the Longitude this way, it also establishes a greater level of consistency and quality in the aircraft’s fit and finish.”

- Ron Draper SVP, Integrated Supply Chain

The vertical tooling structures also include platforms that move up and down to prevent technicians from continuously bending to access horizontally placed components.

The result? Safer and more controlled aircraft builds at a steadier pace.

Since the first prototype took flight in October, the Longitude flight test program has logged more than 290 hours, and the first two aircraft in the program have now completed 142 flights. Up next for the aircraft is a new phase of performance testing, with pilots and engineers refining the aircraft’s systems.